“Made in Italy” parquet

Available in 20 colours responding to the needs of the market.

Italy offers the most advanced structural technology with the innovative use of a multilayer birch support in “sections” which gives the product remarkable stability.

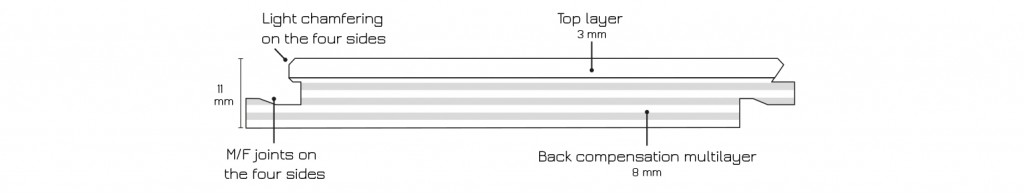

Technical data

Italy 220 – 180 – 150

Characteristics

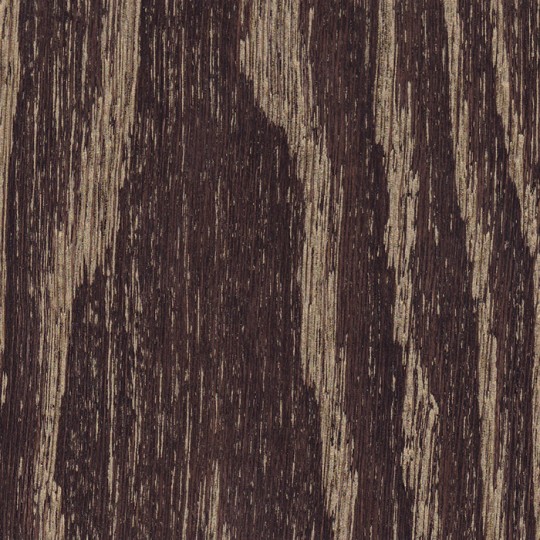

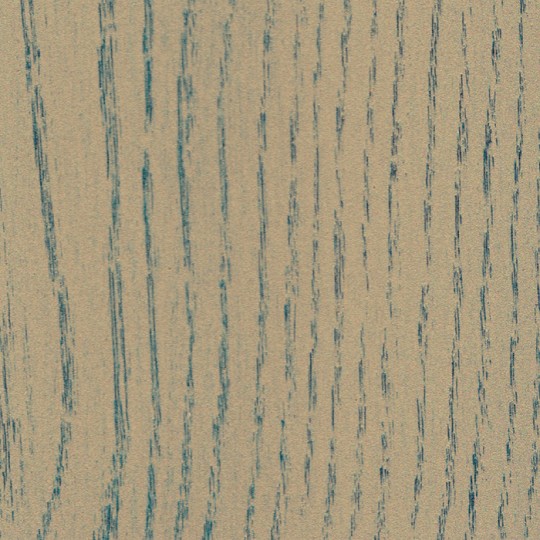

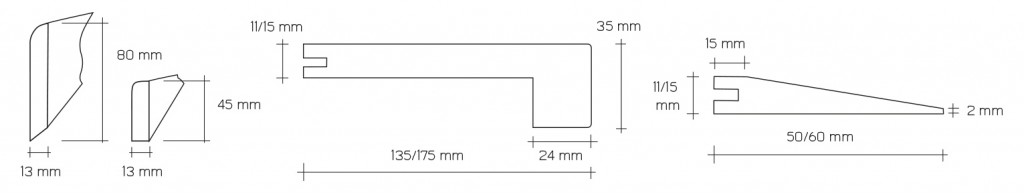

T2-ply engineered floor board with “wax finish” and light surface brushing. It consists of a 3 mm hardwood top layer of European Oak and bottom compensation with multilayered wood. All four sides have traditional male/female joints and light chamfering.Both are available in 20 colour options in the Special or Rustic versions.

Supplies

ITALY 220 – ITALY 180 – ITALY 150: Supplies are provided in several lengths: 1600 /

1800 / 2000 mm

Classification

Special and Rustic options based on the requirements of the European standard (Table UNI EN 13489 for multilayer parquet floor with joint).

Recommended laying

ITALY 220 – ITALY 180 – ITALY 150: with two-component adhesives or floating. Both are

suitable for laying on heating screeds.

thickness:

Italy 220/180/150: 15 mm

width:

Italy 220/180/150: 220/180/150 mm

length:

Italy 220/180/150: mm 1,600 / 1,800 / 2,000 (with possibility of a modest percentage of shorter lengths)

joint:

TavarBlock (without glues) on the long sides; m/f on the short sides

The finishes

“Riflessi” Collection

La Gallery

[metaslider id=2833]

High resistance paint

Floors are for walking and running on and so they must be cleaned regularly. This is why Tavar finishes are tested by our laboratories to ensure resistance to wear and routine maintenance.

Underfloor heating

The entire range of Tavar products has been conceived and produced also for laying on heated screeds maintaining all the product guarantees.

“Made in Italy” Certification

Certification makes it possible to have a guarantee of Italian origin and quality of the products purchased. Certificates are issued by the ITPI (Institute for Protection of Italian Producers) after specific verification of the origin and processing of the product.